LEGAL STATEMENTS | EN | RU

WELDPACK® | best technology

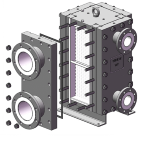

WeldPack which is fully developed, manufactured and patented by Vitherm, is a process heat exchanger which is able to withstand extreme operating conditions, corrosive fluids, high pressure and high temperatures.

Vitherm's WeldPack is fully accessible on both sides, this enables customers to have inspections regularly, easy cleaning and repairing. This is possible due to the unique plates geometry, assembly and patterns, which stands out differently from any other welded heat exchanger available on the market.

- Corrugated plate

Square plate without lugs, more solid construction against hydroblows and cyclic workloads; do not require very close tolerances for adjustment; - Inlet canal - 10 mm

There is no area with laminar flow; - Columns' facing's made of one component

Thickness of columns' facing - 2 mm, mechanically very solid construction; - Welding from reverse side of column's facing

The way of assembly increase durability when cyclic workloads; - Drainage and vetilation connections

Are designed correspondingly in the lowest and in the highest points, there is always possibility for full discharge.

CONSTRUCTION

- easily accessible for regular cleaning of the heart, maintenance & servicing;

- long, low-maintenance lifetime resulting in low life-cycle costs;

- compact and efficient;

- fully welded, but is totally accessible on both sides;

- no interplate gaskets;

- problems associated with conventional plate heat exchangers, are eliminated, e.g. gasket compatibility, temperature and pressure;

- the heart of this unit consists of welded corrugated heat transfer plates of stainless steel or other appropriate exotic metals;

- the frame is just four columns, top and bottom heads and four panels with connections;

- he totally bolted design of Weldpack® allows quick disassembly of the steel frame;

- a 320 m2 square meters WeldPack® only needs 9 m2 of floor space, including maintenance space.