LEGAL STATEMENTS | EN | RU

WASTE TREATMENT | CDM - Clean Development Mechanism

WHAT IS THE KYOTO PROTOCOL'S CLEAN DEVELOPMENT MECHANISM (CDM) ?

The United Nations Framework Convention on Climate Change (UNFCCC) is the UN institution in charge of coordinating research and measures taken in relation with climate change, and fixes target emissions (measured as the equivalent in carbon dioxide) that a Party may emit over the commitment period in order to comply with its emissions target, known as a Party's Assigned Amount. The Kyoto Protocol sketches out "mechanisms" of how industrialized countries can take stronger and more detailed commitments to reduce greenhouse gas emissions (GHG).

UNFCCC: http://unfccc.int/2860.php

Kyoto Protocol: http://unfccc.int/resource/docs/convkp/kprus.pdf

The Kyoto Procotol proposes three mechanisms: CDM (Clean Development Mechanism), JI (Joint Implementation) and ET (Emission Trading). CDM is between Annex-I countries and non-Annex-I countries while the other two are between Annex-I countries.

- CDM, defined in Article 12 provides for Annex I Parties to implement project activities that reduce emissions in non-Annex I Parties, in return for certified emission reductions (CERs).

- JI, under Article 6 of the Kyoto Protocol provides for Annex I Parties to implement projects that reduce emissions, or remove carbon from the atmosphere, in other Annex I Parties, in return for emission reduction units (ERUs).

- ET, as set out in Article 17 of the Kyoto Protocol provides for Annex I Parties to acquire units from other Annex I Parties and use them towards meeting their emissions targets under the Kyoto Protocol.

So the outputs of the three mechanisms are CERs (Certificated Emission Reductions) from CDM, ERUs (Emission Reduction Units) from JI and AAUs (Assigned Amount Units) from ET. They are all representing GHG reductions but playing different roles in emission trading. For example, CERs need to be transferred into ERUs or AAUs when traded between Annex-I countries.

WHICH GREENHOUSE GASES ARE CONCERNED ?

The object of the Kyoto Protocol is to reduce emissions of six main greenhouse gases, namely:

| GAS | SOURCE | Global Warming Potential (GWP) |

|---|---|---|

| Carbon dioxide (CO2) | Biomass respiration and burning land-use change, energy, transport, industry etc. | 1 |

| Methane (CH4) | Energy, landfills, ruminants, waste treatment, rice agriculture, biomass burning etc. | 21 |

| Nitrous oxide (N2O) | Transport, industry, livestock and feed, biomass burning etc. | 310 |

| Hydrofluorocarbons (HFCs) | Refrigeration and air-conditioning industries, firefighting agents | 140 ~ 11,700 |

| Perfluorocarbons (PFCs) | Electronics industry processes | 6,500 ~ 9,200 |

| Sulphur hexafluoride (SF6) | Dielectric gas for high voltage applications | 23,900 |

The figure in the last column shows that not all GHGs have the same impact on climate change: Global Warming Potential is the ratio of the warming caused by a substance to the warming caused by a similar mass of carbon dioxide. CFC-12, for example, has a GWP of 8,500, while water has a GWP of zero.

Therefore, implementing a project for the destruction of fluorocarbons will have a terrific positive impact on climate change, and considerably contribute to lowering emissions so as to reach targets.

HOW IS THIS IMPLEMENTED IN PRACTICE ?

Project participants wishing to adopt / register CDM projects have the opportunity to:

- use the methodology previously approved by the Executive Council

- or propose to the Executive Council of a new methodology for the study. If this methodology complies with the relevant requirements, it will be approved.

VICHEM offers a unique technology projects for the destruction of fluorocarbons based on thermal oxidation. This technology has been approved by the CDM Executive Council No. AM0001. Below there is a link to the website that hosts the document approving the project on thermal oxidation HCF-23 (GWP HCF-23 is 11 700).

http://cdm.unfccc.int/UserManagement/FileStorage/AM0001_version3%20.pdf

In addition, a scientific study "Suitable alternative fluorocarbons in terms of the environment" (full version in English: http://www.afeas.org), shows a trend (full version in English: http://www.afeas.org /production_and_sales.html) to reduce the production of fluorocarbons. Of the ten companies operating in the chemical industry and to participate in this study, three are clients of VICHEM and use our proposed system thermal oxidation of waste fluorinated gases.

WHY IS VICHEM'S TECHNOLOGY THE BEST ONE ?

HFC23 gas is very stable and it is extremely difficult to destroy, and VICHEM has the experience and expertise to solve four main problems associated with the decomposition of HFC23:

- Time spent. According to the European Directive 2000/76/EC and American standard (EPA's Standards for Hazardous Air Pollutants for Hazardous Waste Combustors), if the flue gas has more than 1% of halogen-containing compounds, expressed in chlorine content, they should have a controlled temperature of destruction at least 1100 ° C (we chose the 1200 ° C) and time spent at least 2 seconds. This applies to most installations HCFC22, for which the exhaust gases are a mixture of HFC23 et de HCFC22. VICHEM developed Inconel furnace with a special refractory material (high alumina content and silica content of zero), to provide a residence time is two seconds. Independent of the furnace burners have flame inside. Any other system is not providing for the time spent does not correspond to European or American standards.

- Turbulent flame. VICHEM developed and patented an advanced burner system called Pulvaporizator® which creates very high turbulence, to obtain a homogeneous mixture of flue gases, liquids and steam and if necessary combustion air. Thus, HFC23 destroyed with DRE (Decomposition Efficiency and Remote) to 99.999%, without the formation of byproducts.

- Dioxins. How to avoid formation of by-products such as dioxins? Pulvaporizator by VICHEM, due to the very high turbulence decomposition has outstanding efficiency at which no by-product is formed at this stage. In systems of our competitors, dioxins are formed again during the cooling phase, where the flue gases are at a temperature between 250 ° C and 400 ° C. This process in the system prevented VICHEM, as we have developed for the flue gases sprinkling apparatus (Quench), reducing the temperature from 1200 °C to 50 °C within a few thousandths of a second. Passing through this temperature range, dioxins are formed too quickly, in order to finally form. The concept of our competitors instead of the Quench device uses cooling chamber where dioxins have every chance to emerge as the cooling is slow.

- Monitoring and measurement of gases. Measurements and analysis of gases at the inlet and outlet of the installation - one of the most problematic issues for CDM projects for processing HFC23. With over 60 years of experience in the design, installation and commissioning of systems into use for the processing of hazardous industrial waste, VICHEM has created and amassed a varied and extensive knowledge in the field of control and measurement of gases, so we can consider the most accurate and cost-effective solution to meet the requirements put forward by the CDM Executive Council.

WHERE ARE THESE FLUORINATED GASES FOUND ?

HFCs

| Designation | Main applications |

|---|---|

| HFC-23 | - By-products in production of HCFC-22 - Low temperature refrigerants - Firefighting agents |

| HFC-32 | Blend component for air conditioning equipment and commercial refrigeration |

| HFC-43-10mee | Solvents for special applications |

| HFC-125 | - Blend components for conditioning and commercial refrigeration - Firefighting agent |

| HFC-134a | - Blend components for mobile and stationary air conditioning, and for domestic refrigerators / freezers - Propellant for extruded polystyrene foams (XPS) |

| HFC-143a | Blend components for air conditioning equipment and commercial regrigeration |

| HFC-152a | - Propellant for specialised industrial aerosols - Blowing agent component for extruded polystyrene foams (XPSS) |

| HFC-227ea | - Propellant for medical aerosols - Firefighting agents |

| HFC-236fa | Firefighting agents |

| HFC-245fa | - Foam blowing agent for polyurethane (PUR) foams |

| HFC-365mfc | - Foam blowing agent for polyurethane (PUR) and phenolic foams - Blend components for solvents |

PFCs

PFC gases and liquids are traditionally used in several electronics industry processes ranging from semiconductor front-end manufacturing, IC-components quality control testing to direct contact dielectric cooling of e.g. power electronics assembly.

SF6

Sulphur hexafluoride (SF6) is an excellent dielectric gas for high voltage applications.

WHAT ARE THE RESULTS AND THEIR FINANCIAL IMPACT ?

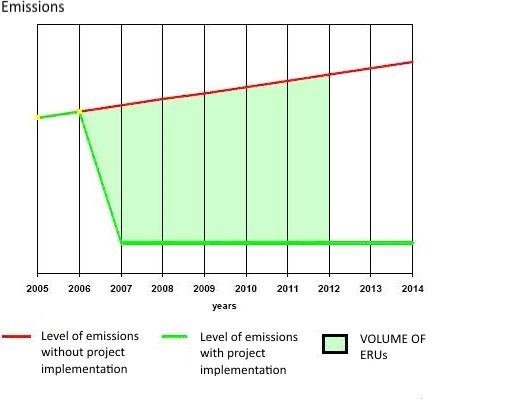

The diagramme below shows the evolution of emissions without implementing a project (in red). This is increasing because it takes into consideration the hypothesis of production increase. Then in green is the evolution of emissions when a project is implemented. The light green zone shows the volume of emissions that can be traded. It stops in 2012 because the current scheme only is valid until 2012, it will very soon be discussed of how the scheme will evolve after 2012.

This shows the amount that can therefore be gained per year by trading:

Emission credits x GWP x Market price

In private enterprise, emissions trading is very attractive because it does not harm industrial concerns, or require government subsidies. When the price per ton of emissions becomes high enough, well-managed polluting enterprises can make a rational decision to invest in pollution control equipment, and sell part of their emissions licenses.